Piston

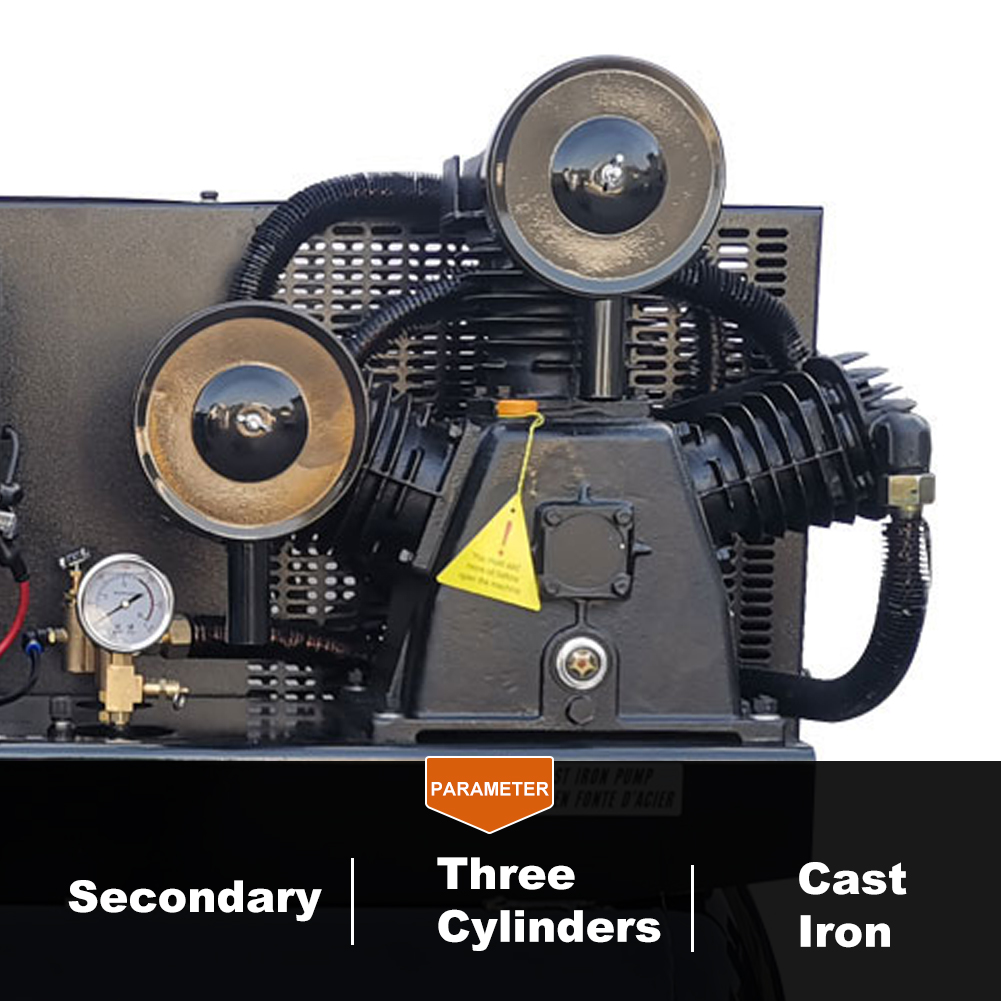

Piston air compressors are the most commonly used industrial air compressors, operating on displacement principles to increase the pressure of enclosed air. They utilize a valve system with two stainless steel discs: as the piston moves downward, the largest disc folds, allowing air to enter the cylinder. When the piston moves upward, the disc seals against the valve seat, compressing the air, which is then forced through an opening in the seat and delivered to the end process.

Key advantages of piston compressors include affordability, low maintenance, and easy access to spare and replacement parts. However, they tend to produce more noise and heat and have a higher risk of oil contamination in the compressed air.

Sort by

Latest

W2090 Air Pump For 13hp 175psi Gas Air Compressor

W2090 Air Pump For 13hp 175psi Gas Air Compressor

$900.00

Throttle control valve for HPDMC 6.5-13Hp gasoline piston engine

Throttle control valve for HPDMC 6.5-13Hp gasoline piston engine

$150.00

Piston Air Compressor With Vertical Type Air Tank

The HPDMC Compressor W Series one-stage or two-stage piston air end is available in simplex or duplex configurations with a vertical or horizontal tank depending on the model selected. The heavy duty cast-iron construction makes the compressor ideal for tough working conditions. The W Series features stainless steel reed valves with valve bumpers, industrial ball bearings, two-piece aluminum connecting rods, fin and tube intercooler, automotive style inlet filter/silencer, and a ductile iron, double throw crankshaft. The aluminum head dissipates heat to ensure the compressor is running as cool as possible while the valve design provides high volumetric efficiency. 3 to 10 HP models have an automatic start/stop, while 15 HP models have a dual controller. All W Series compressor models come with an NEMA motor, motor overload protection, and a ball valve tank drain.

Starting at $5,500.00

4500psi Pcp/Paintball Game/Scuba/Scba Refilling High-Pressure Air Compressor

The SCU Series 4500 PSI Portable Scuba Diving/PCP Compressor is a reliable, and they have a reduced price but features the same high quality and dependable performance can rely on.

Starting at $4,679.00

Portable Gasoline Power Piston Air Compressor 6.5HP

Portable 6.5 HP compressor with KOHLER gas engine

$1,199.00

Starting at $799.00

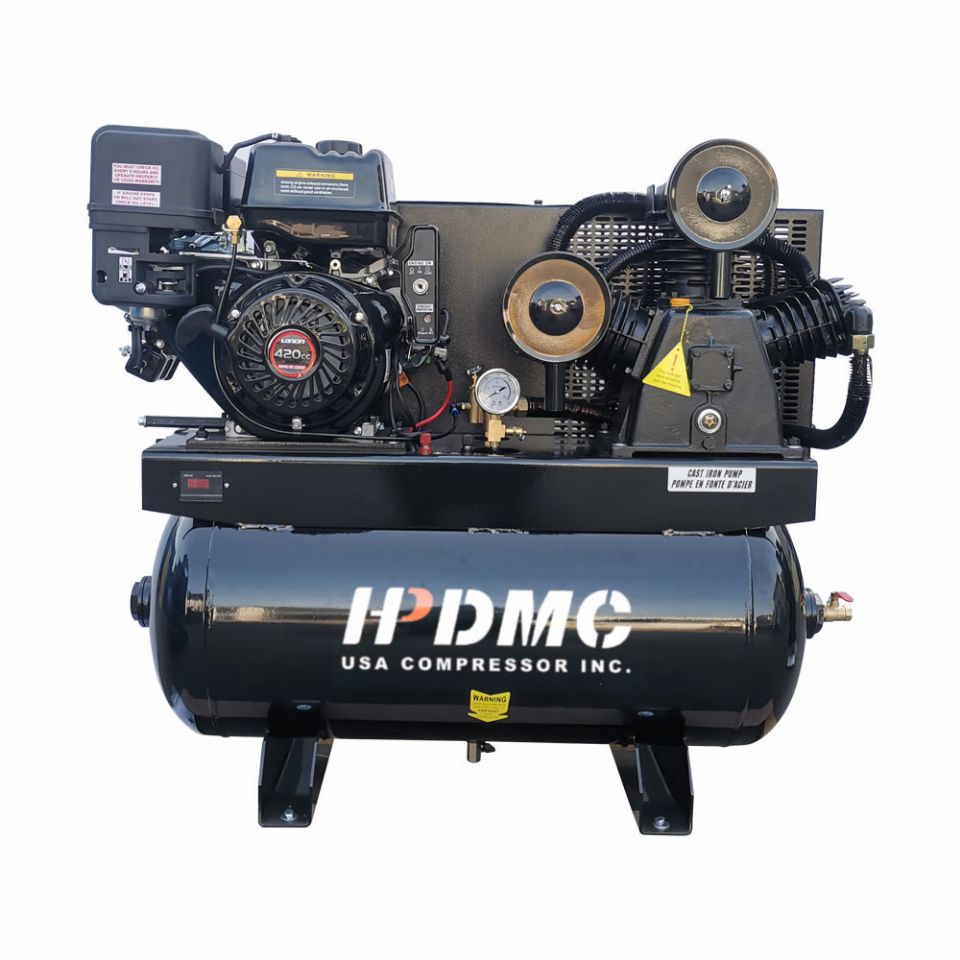

Gasoline Power Piston Air Compressor 13HP

13 HP compressor with LONXIN gas engine with pull and electric starting.

Starting at $3,339.99

4500psi Pcp/Paintball Game Refilling High-Pressure Air Compressor

The SCU Series 4500 PSI Portable PCP Compressor is a reliable, and they have a reduced price but features the same high quality and dependable performance shooters can rely on.

Starting at $749.99

Diving Air Compressor With Hose and Respirator

With the SCU hookah system for diving, you can explore underwater worlds with streamlined freedom of movement like when snorkeling

Starting at $1,449.99

© 2025 HPDMC Air Compressor.All Rights Reserved. Friendly links: Davyenergy; DBC; Auto-Hydra; LiveShelf

DMC USA COMPRESSOR INC websites place cookies on your device to give you the best user experience. By using our websites, you agree to the placement of these cookies. To learn more, read our Privacy Policy and Terms of Use

ACCEPT & CLOSE